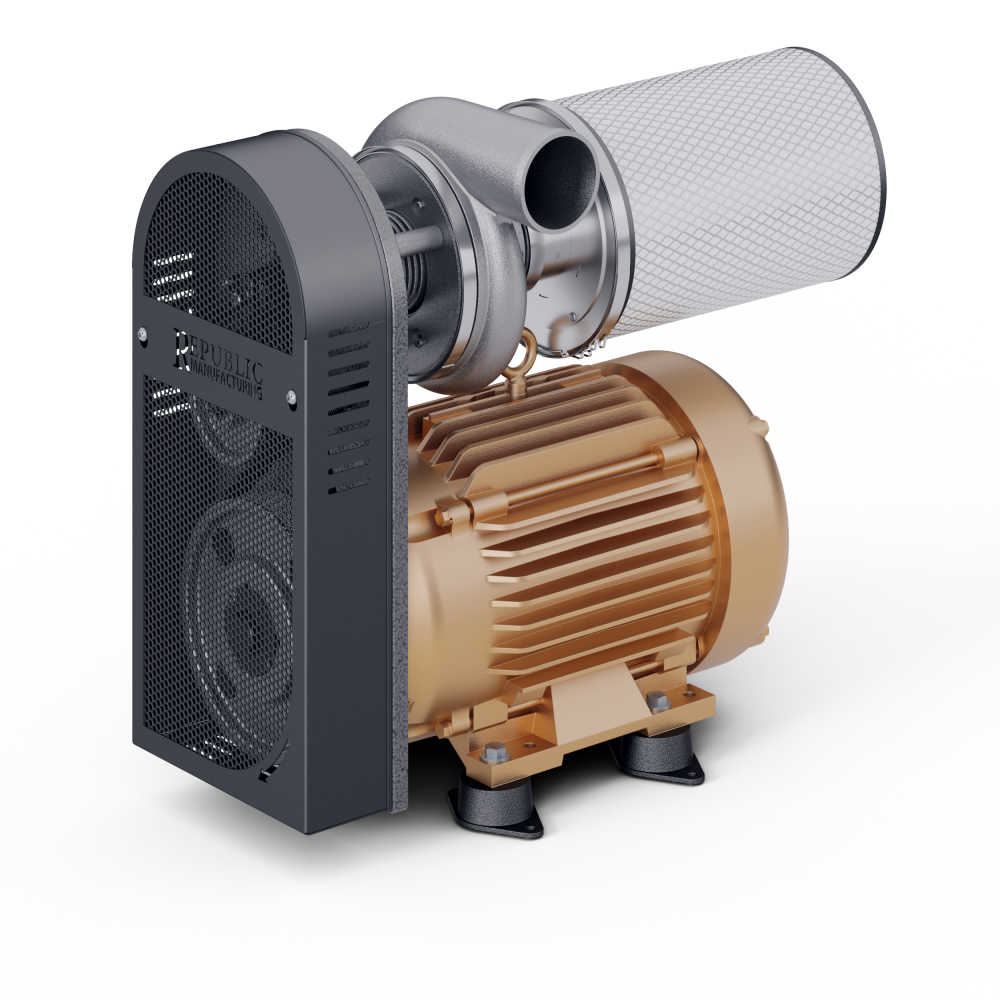

Single Stage Centrifugal Blowers

Efficient Single Stage Centrifugal Blower Performance

Single stage centrifugal blowers are engineered to deliver reliable, high-volume airflow with smooth, energy-efficient operation. Designed for applications requiring steady, non-pulsating air movement, these blowers provide a powerful yet compact solution that integrates easily into a wide range of industrial systems, from material handling and drying processes to cooling, ventilation, and general air support. Built with precision-balanced impellers and durable housing, single stage centrifugal blowers offer consistent performance with minimal vibration and noise. Their streamlined design ensures efficient airflow at moderate pressure levels while keeping maintenance requirements low and system uptime high. With multiple horsepower, speed, and mounting configurations available, these blowers deliver dependable performance tailored to your facility’s operating needs.

Types of Single Stage Centrifugal

RB Series – Centrifugal Blowers

The Republic RB Series centrifugal blowers are designed to deliver reliable, oil-free airflow for vacuum and compressed air applications across a wide range of industrial environments. Built with decades of proven performance, the RB Series supports applications such as material handling, vacuum hold-down, drying, and general process air where consistent flow and low maintenance are critical. These belt-driven blowers provide dry, clean air with lower energy consumption compared to compressed air systems, while safely operating at low pressure to support increased production speeds and system efficiency.

Available Models: RB500, RB800, RB1200HC, RB2000, RB4002

RBX Series – High-Efficiency Centrifugal Blowers

The Republic RBX Series centrifugal blowers are engineered for high-duty applications requiring maximum efficiency and long-term reliability. Designed to generate high airflow and pressure, the RBX Series supports demanding uses such as aeration, drying and blow-off, vacuum hold-down, and vapor transfer. With peak efficiencies up to 80 percent, reduced power consumption, smaller motor requirements, and extended bearing life, the RBX Series addresses common concerns around operating cost, uptime, and maintenance intervals. Robust construction and flexible configuration options make the RBX Series well suited for continuous industrial operation.

Available Models: RBX-150, RBX-250, RBX-400

Optional Features & Accessories

Available options include sound and environmental enclosures, specialty motors (explosion-proof, wash down, IEC, or NEMA Premium), stainless steel construction, inlet and outlet flanges, water-cooled configurations, and chemically resistant seals.

Industrial & Commercial Markets Served

Wastewater • Oil & Gas • Chemical • Packaging • Glass • Plastics • Industrial Automation

Key Design Advantages

Durable, High-Performance Construction

Built with long-life components including a 10-groove belt, 6061-T6 aluminum impeller (RBX-Series), stainless steel and zinc-plated pulleys, and a rugged steel motor housing for maximum reliability.

Service-Friendly Design

Features a rotatable discharge and an easy-to-remove bearing/impeller housing, allowing quick maintenance and fast component replacement to minimize downtime.

Precision Engineering for Smooth Operation

Ceramic hybrid bearings, PTFE shaft seals on both sides of the bearing assembly, and 100% operational performance and vibration testing ensure consistent, high-efficiency performance.