Compressed Air Quality Testing

Compressed Air Quality Testing Services

Why is it Important?

Compressed air use in your manufacturing process must be controlled and monitored to provide a level of quality that meets your requirements. If compressed air comes into contact either directly or indirectly with your product, it must be considered as a potential hazard.

What do we test?

Particles – Rust, dirt, and metal shavings are just a few examples of possible particle contamination.

Water – Length and condition of distribution piping, drops, dead-ends, condensate drain traps, and the use of polymer tubing can contribute to excess moisture.

Oil – Even oil-free compressors can be contaminated with oil vapor (gaseous hydrocarbons) from intake air.

Microorganisms – An improperly maintained compressor may provide the conditions (water + oil + warm temperature) needed for microbial growth.carbons) from intake air.

Science Made Easy!

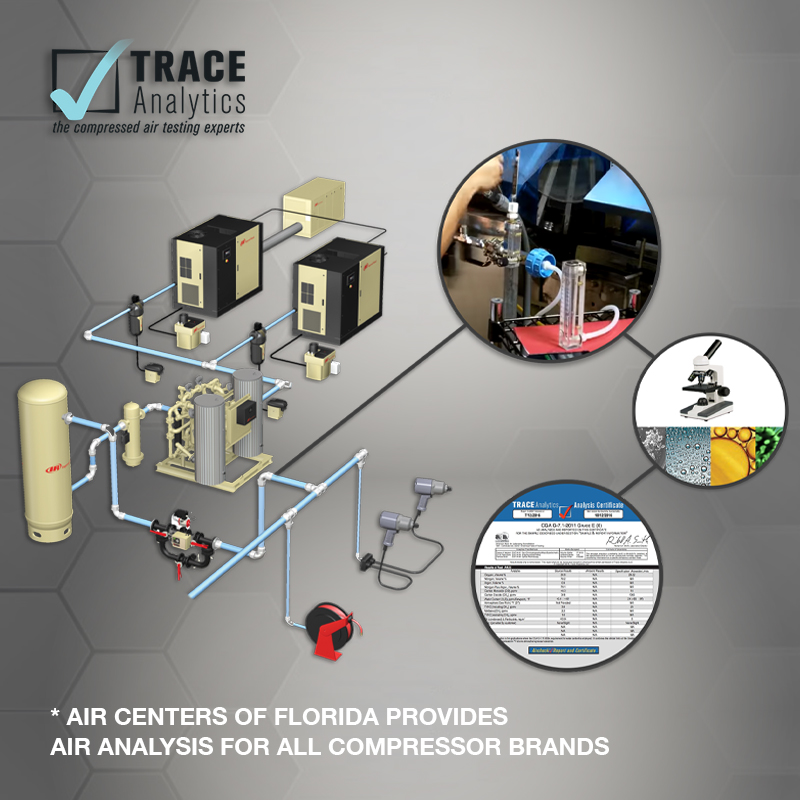

We’ve partnered with Trace Analytics, an ISO 17025 accredited laboratory for your compressed air testing needs.

Here’s What you can Expect:

– End to end support from qualified staff

– Quick turn around for audits – Accurate results

– Help meeting ISO standards